How To Cut Polyester: Applications, Methods And Tips

How to Cut Polyester: Applications, Methods And Tips

Introduction:

Key Things to Know Before Diving In

Polyester is a go-to fabric for clothing, upholstery, and industrial use because it’s durable, versatile, and easy to care for. But when it comes to how to cut polyester, using the right method makes all the difference. Clean edges and a professional finish depend on proper techniques that prevent fraying and ensure accuracy.

In this guide, we’ll walk you through popular cutting options—manual tools, CNC knife systems, and laser cutting—while sharing practical tips to make your projects easier. By weighing the pros and cons of each approach, you’ll be able to choose the method that fits your needs best, whether it’s for sewing, manufacturing, or custom designs.

Table of Contents:

The most common application of polyester is in fabrics. Polyester fabric has properties that make it ideal for use as clothing due to its durability, low cost, and resistance to staining. Even though polyester is not inherently breathable, modern advancements in fabric engineering, such as moisture-wicking technologies and specialized weaving methods, have made it a popular choice for breathable thermal and athletic clothing. Moreover, polyester is typically blended with other natural fabrics to increase comfort and reduce the amount of creasing that is common with polyester. Polyester fabric is one of the most widely used textiles on the planet.

▶ Applications Of Polyester In Industry

Polyester is widely used in industrial applications due to its high tensile strength, durability, and resistance to stretching. In conveyor belts, polyester reinforcement enhances strength, rigidity, and splice retention while reducing friction. In safety belts, densely woven polyester ensures durability and reliability, providing critical protection in automotive safety systems. These properties make polyester an essential material in industries requiring strong and long-lasting textile reinforcements.

How to Cut Polyester Fabric Without Fray ?

Polyester is a popular fabric choice due to its durability and versatility, but cutting it can be tricky. One common issue is fraying, where the fabric’s edges unravel and create a messy finish. Whether you’re a DIY enthusiast or a professional seamstress, achieving clean, fray-free cuts is essential for a polished look.

▶ Why Does Polyester Fabric Fray?

Cutting Method

The way polyester fabric is cut plays a crucial role in its tendency to fray. If dull scissors or a blunt rotary cutter are used, they can create uneven, jagged edges that unravel more easily. To achieve clean edges with minimal fraying, sharp and precise cutting tools are essential.

Handling and Using

Regular handling and frequent use of polyester fabric can gradually lead to fraying at the edges. The friction and pressure exerted on fabric edges, especially in areas subject to constant wear, can cause fibers to loosen and unravel over time. This issue is commonly observed in clothing and other frequently used textile items.

Washing and Drying

Incorrect washing and drying methods can contribute to polyester fabric fraying. Excessive agitation during washing, particularly in machines with agitators, can roughen fabric edges and lead to fraying. Additionally, exposure to high heat during drying can weaken the fibers, making them more prone to unraveling.

Edge Finish

The way the fabric’s edges are finished greatly influences its likelihood of fraying. Raw edges without any finishing treatment are far more susceptible to unraveling than those that have been properly sealed. Techniques such as serging, overlocking, or hemming effectively secure fabric edges, preventing fraying and ensuring long-term durability.

▶ How To Cut Polyester Fabric Without Fraying?

1. Finish the Raw Edges

A reliable way to prevent fraying is by finishing the raw edges of the fabric. This can be done by sewing a narrow hem along the edges, either with a sewing machine or by hand, to enclose the raw fabric and create a neat, polished look. Alternatively, an overlock stitch or a serger can be used to reinforce the edges, offering a professional finish while effectively preventing fraying.

2. Use Heat to Seal the Edges

Applying heat is another effective method for sealing polyester edges and preventing fraying. A hot knife or soldering iron can be used to carefully melt the fabric edges, creating a sealed finish. However, since polyester is a synthetic material, excessive heat can cause it to melt unevenly or even burn, so caution is necessary when using this technique.

3. Use Fray Check on the Cut Edges

Fray Check is a liquid sealant designed to prevent fabric edges from unraveling. When applied to the cut edges of polyester fabric, it dries into a flexible, clear barrier that holds fibers in place. Simply apply a small amount to the edges and let it dry completely. Fray Check is widely available in fabric stores and is a useful addition to any sewing kit.

4. Use Pinking Shears when Cutting

Pinking shears are specialized scissors with serrated blades that cut fabric in a zigzag pattern. This pattern helps reduce fraying by limiting the unraveling of fibers and providing a more secure edge. Pinking shears are especially beneficial when working with lightweight polyester fabrics, offering an easy and effective way to improve fabric durability.

▶ How To Laser Cut Polyester? | Video Display

Matching Polyester Types With The Right Cutting Method

Unlocking the secrets to fast and automatic sublimation sportswear cutting, the MimoWork vision laser cutter emerges as the ultimate game-changer for sublimated clothing, including sportswear, leggings, swimwear, and more. This cutting-edge machine introduces a new era in the world of apparel production, thanks to its accurate pattern recognition and precise cutting capabilities.

Dive into the realm of high-quality printed sportswear, where intricate designs come to life with unparalleled precision. But that’s not all – the MimoWork vision laser cutter goes above and beyond with its auto-feeding, conveying, and cutting features.

Camera Laser Cutter for Sportswear & Clothing

We’re diving into the realms of advanced and automatic methods, exploring the wonders of laser cutting printed fabrics and activewear. Equipped with a cutting-edge camera and scanner, our laser cutting machine takes efficiency and yields to unprecedented heights. In our captivating video, witness the magic of a fully automatic vision laser cutter designed for the world of apparel.

The dual Y-axis laser heads deliver incomparable efficiency, making this camera laser-cutting machine a standout performer in laser cutting sublimation fabrics, including the intricate world of jersey materials. Get ready to revolutionize your approach to laser cutting with efficiency and style!

solid ventilation system in place is super important.

● Best Suited For:

Large-scale textile manufacturing.

Industries requiring high-precision, intricate designs

Here is a chart which provides a comprehensive overview of the most suitable cutting methods for different types of polyester fabric. It compares manual cutting, CNC vibrating knife cutting, and laser cutting, helping you choose the best technique based on the specific polyester material you’re working with. Whether you are cutting heavy-duty, delicate, or high-detail polyester, this chart ensures that you select the most efficient and precise cutting method for the best results.

Matching Polyester Types With The Right Cutting Method

Start A Conversation

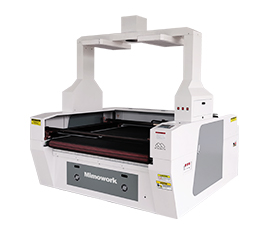

Recommended Machine For Laser Cut Polyester

To achieve the best results when cutting polyester, choosing the right polyester laser cutting machine is crucial. MimoWork Laser offers a range of machines that are ideal for laser cutting polyester, including:

• Working Area (W *L): 1600mm*1200mm

• Laser Power: 100W/130W/150W

• Working Area (W *L): 1800mm*1300mm

• Laser Power: 100W/130W/300W

Sublimation Polyester Laser Cutter (Fully-Enclosed)

• Working Area (W *L): 1800mm*1300mm

• Laser Power: 100W/130W/150W/300W

You May Be Interested

Talk with Us

Last Updated: January 5th,2026

• Laser Power: 100W/130W/300W

Sublimation Polyester Laser Cutter (Fully-Enclosed)

• Working Area (W *L): 1800mm*1300mm

• Laser Power: 100W/130W/150W/300W

You May Be Interested

Talk with Us

Talk with Us

Last Updated: January 5th,2026