Mimo Contour Recognition System

Contour Recognition System

Why You Need Mimo Contour Recognition System?

With Mimo Contour Recognition System, You Can

• Easily recognize different sizes and shapes of graphics

You can print all your designs, regardless of size and shape. No need for a strict classification or layout.

• No need for cutting files

The laser contour recognition system will automatically generate the cutting outline. No need to prepare the cutting files in advance. Eliminate the need for the conversion from the PDF print format file to the cutting format file.

• Achieve Ultra-high-speed recognition

The contour laser recognition only takes only 3 seconds on average which greatly improves the production efficiency.

• Large recognition format

Thanks to the Canon HD camera, the system has a very wide angle of view. Whether your fabric is 1.6m, 1.8m, 2.1m, or even wider, you can use the contour laser recognition system to laser cut.

Vision Laser Cutting Machine with Camera

Sublimation Laser Cutter

• Laser Power: 100W / 130W / 150W

• Working Area: 1600mm * 1200mm (62.9” * 47.2”)

Dual Heads Contour Laser Cutter

• Laser Power: 100W / 130W / 300W

• Working Area: 1800mm * 1300mm (70.87’’ * 51.18’’)

Fully Enclosed Vision Laser Cutter

• Laser Power: 100W / 130W / 300W

• Working Area: 1800mm * 1300mm (70.87’’ * 51.18’’)

Workflow of Mimo Contour Recognition Laser Cutting

As it is an automatic process, few technical skills are required for the operator. One can operate a computer can complete this task. The whole process is very simple and easy for the operator to conduct. MimoWork provides the brief contour cutting guide for your better understanding.

1. Auto-Feeding Fabric

Roll to roll feeding

Realizing continuously processing

(with the auto-feeder)

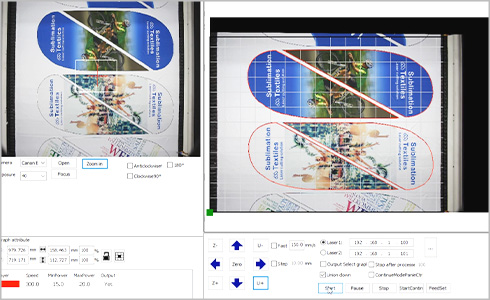

2. Recognizing Contours Automatically

HD camera taking pictures of fabric

Automatically recognizing printed pattern contours

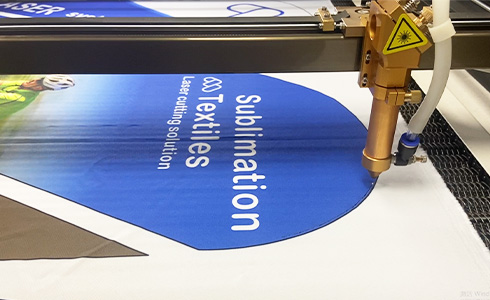

3. Contour Cutting

High speed and precise cutting

No need for additional trimming

(with the camera laser cutting machine)

4. Sorting and Rewinding Cutting Pieces

Conveniently collecting cutting pieces

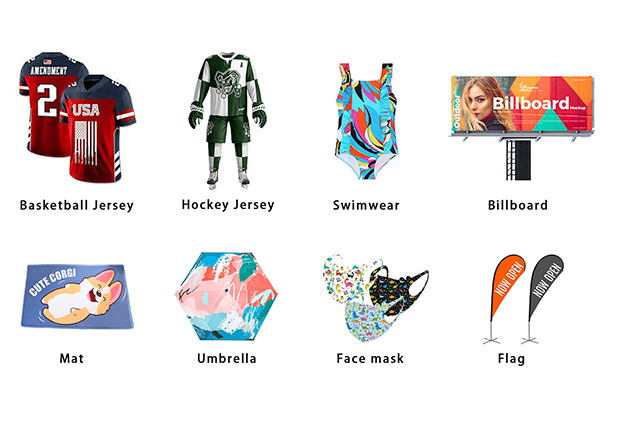

Suitable Applications from Contour Laser Recognition

>> More sublimation fabric laser cutting

Wall Cloth, Active Wear, Arm Sleeves, Leg Sleeves, Bandanna, Headband, Rally Pennants, Face Cover, Masks, Rally Pennants, Flags, Posters, Billboards, Fabric Frames, Table Covers, Backdrops, Printed Embroidery, Appliques, Overlaying, Patches, Adhesive Material, Paper, Leather…

Related Links:

>> Sublimation Fabrics Laser Cutting