Magic with the Sublimation Polyester Laser Cutter: A Review by Ryan from Austin

Magic with the Sublimation Polyester Laser Cutter:

A Review by Ryan from Austin

Background summary

Ryan based in Austin, he has been working with Sublimated Polyester Fabric for 4 years now, he was used to CNC knife for cutting, but just two years ago, he saw a post about laser cutting sublimated polyester fabric, so he decided to give a try.

So he went online and found that on youtube a channel called Mimowork Laser posted a Video about laser cutting sublimated polyester fabric, and the final result looks very clean and promising. Without any hesitation he went online and did a huge amount of research on Mimowork to decide whether buying his first laser cutting machine with them was a good idea. Finally he decided to give it a shot and shot they an email.

Interviewer (Mimowork’s After Sales Team):

Hey there, Ryan! We’re excited to hear about your experience with the Sublimation Polyester Laser Cutter. Can you tell us how you got started in this line of work?

Ryan:

Absolutely! First of all, greetings from Austin! So, about four years ago, I dabbled in working with sublimated polyester fabric using CNC knives. But a couple of years back, I came across this mind-blowing post about laser cutting sublimated polyester fabric on Mimowork’s YouTube channel. The precision and cleanliness of the cuts were out of this world, and I thought, “I’ve got to give this a shot.”

Interviewer: That sounds intriguing! So, what led you to choose Mimowork for your laser cutting needs?

Ryan: Well, I did some extensive research online, and it was clear that Mimowork was the real deal. They seemed to have a solid reputation, and the video content they shared was so insightful. I figured if they could make laser cutting sublimated polyester fabric look that good on camera, imagine what their machines could do in real life. So, I reached out to them, and their response was quick and professional.

Interviewer: That’s great to hear! How was the process of purchasing and receiving the machine?

Ryan: The purchasing process was a breeze. They guided me through everything, and before I knew it, my Sublimation Polyester Laser Cutter (180L) was on its way. When the machine arrived, it was like Christmas morning in Austin – the package was intact and beautifully wrapped, and I couldn’t wait to get started.

Interviewer: And how has your experience been using the machine for the past year?

Ryan: It’s been incredible! This machine is a true game-changer. The precision and speed at which it cuts sublimated polyester fabric are mind-blowing. The sales team at Mimowork has been a delight to work with. Rarely have I encountered any issues, but when I did, their support was top-notch – professional, patient, and available whenever I needed them. Whatever I met some problems about laser cutting, MimoWork Laser team will answer me and solve the questions soon.

Interviewer: That’s fantastic! Is there a particular feature of the machine that stands out to you?

Ryan: Oh, definitely! The Contour Recognition System with the HD Camera is a game-changer for me. It helps me achieve even more intricate and precise cuts on sublimated sportswear, leggings, teardrop flags, and other home textiles, elevating the quality of my work to a whole new level. And the Automatic Feeding System is like having a helpful sidekick – it streamlines my workflow and keeps things moving smoothly.

Interviewer: Sounds like you’re really making the most of the machine’s capabilities. Can you sum up your overall impression of the Sublimation Polyester Laser Cutter?

Ryan: Sure thing! This purchase has been a smart investment. The machine delivers outstanding results, the Mimowork team has been nothing short of amazing, and I’m excited to see what the future holds for my business. The Sublimation Polyester Laser Cutter has given me the power to create with precision and finesse – a truly promising journey ahead!

Interviewer: Thank you so much, Ryan, for sharing your experience and insights with us. It’s been a pleasure talking to you!

Ryan: The pleasure’s all mine. Thanks for having me, and greetings to the whole Mimowork team from Austin!

How to choose laser machine for cutting polyester

What is contour laser cutter (camera laser cutter)

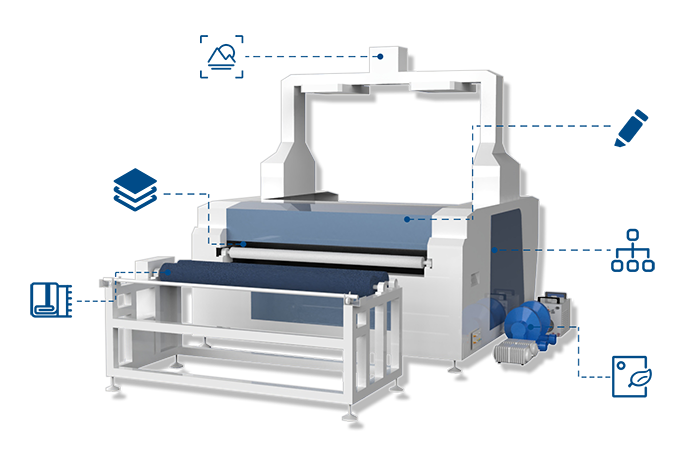

A contour laser cutter, also known as a camera laser cutter, uses a camera system to recognize the outline of printed fabric and then cut out the printed pieces. The camera is mounted above the cutting bed and captures an image of the entire fabric surface.

The software then analyzes the image and identifies the printed design. It then creates a vector file of the design, which is used to guide the laser cutting head. The vector file contains information about the position, size, and shape of the design, as well as the cutting parameters, such as laser power and speed.

Video Display: laser cut sublimated polyester

Dual Heads Laser Cutting Sportswear

Camera Laser Cutting Swimwear (spandex & lycra)

Sublimation Laser Cutter for Teardrop Flag

Laser Cutting Sublimation Pillowcase

Recommended Polyester Laser Cutter

Sublimation Polyester Laser Cutter 160L

Sublimation Polyester Laser Cutter 180L

Sublimation Polyester Laser Cutter (Fully-Enclosed)

Have no idea about how to choose suitable sublimation polyester laser cutter?

What is sublimation polyester

Polyester is a synthetic polymer that is commonly used to create fabrics and textiles. It is a strong and durable material that is resistant to wrinkles, shrinking, and stretching. Polyester fabric is commonly used in clothing, home furnishings, and other textiles, as it is versatile and can be manufactured in a variety of weights, textures, and colors.

Polyester fabric is a versatile and durable material that is used in a wide range of applications, and laser cutting can provide many benefits in terms of precision, efficiency, and design.

Dye sublimation is a printing technique that transfers designs onto fabric using heat and pressure. This technique is commonly used to create custom designs on polyester fabric. There are several reasons why polyester fabric is the preferred fabric for dye sublimation printing:

>> learn more polyester laser cutting

1. Heat resistance:

Polyester fabric is able to withstand the high temperatures required for dye sublimation printing without melting or distorting. This allows for consistent and high-quality results.

2. Vibrant colors:

Polyester fabric is able to hold vibrant and bold colors, which is important for creating eye-catching designs.

3. Durability:

Polyester fabric is durable and resistant to shrinking, stretching, and wrinkles, which makes it ideal for creating long-lasting and high-quality products.

4. Moisture-wicking:

Polyester fabric has moisture-wicking properties, which helps to keep the wearer cool and dry by drawing moisture away from the skin. This makes it a popular choice for athletic wear and other products that require moisture management.

Benefits from camera laser cutter for polyester

The camera system ensures that the laser cutter cuts along the exact contours of the printed design, regardless of the shape or complexity of the pattern. This ensures that each piece is cut accurately and precisely, with minimal waste.

Contour laser cutters are particularly useful for cutting fabric with irregular shapes, as the camera system can identify the shape of each piece and adjust the cutting path accordingly. This allows for efficient cutting and minimizes fabric waste.

Conclusion

Overall, contour laser cutters with cameras are a popular choice for cutting printed fabric, and sublimation fabrics, as they offer high precision and accuracy, and can handle a wide variety of designs and shapes.