Laser Cutter Fume Extractor

Laser Cutter Fume Extractor

Breathe Easy: Fume Extractors for a Cleaner, Safer Workspace

Laser cutting, engraving, and welding produce harmful fumes, toxic gases, and fine dust.

Posing health risks and disrupting productivity.

Without proper extraction, these byproducts linger in the air.

Damaging equipment and violating safety regulations.

Not all fumes are the same.

A Standard Exhaust Fan isn’t Enough.

Proper Filtration ensures Clean Air and Regulatory Compliance.

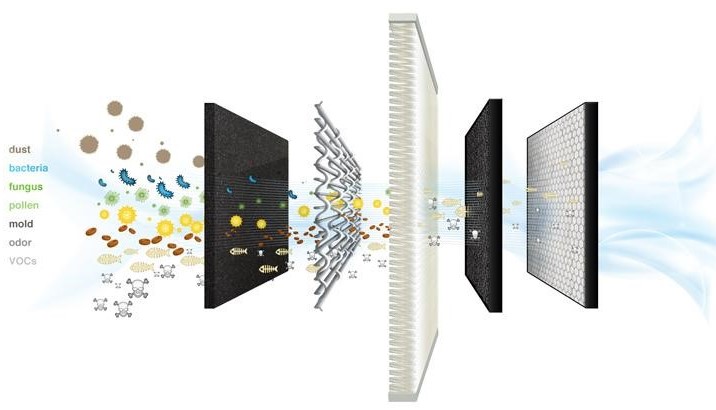

Filtration Process of Laser Cutter Fume Extractor

Interested in Laser Fume Extractor?

E-mail: info@mimowork.com

WhatsApp: [+86 173 0175 0898]

Why You Need a Laser Fume Extractor

Laser Cutter Fume Extractor

At MimoWork, we provide Industrial-Grade Laser Fume Extractors designed to:

1. Remove Hazardous Fumes (Acrylic, Fiberglass, Metals, etc.)

2. Eliminate Strong Odors with Advanced Activated Carbon Filters

3. Protect your Team from Respiratory Hazards

4. Extend Machine Lifespan by Reducing Internal Dust Buildup

5. Meet Environmental & Workplace Safety Standards

Different Materials Require Specialized Filtration

Some Materials (like Fiberglass or Rust Removal) produce Ultra-Fine Particles that need Specialized Capture Systems.

Besides, MimoWork’s Research on Numerous Materials and Dust (Dry, Oily, Sticky) generated by Laser Cutting and Laser Engraving.

Ensuring that our Laser Fume Extraction Solutions are the Best Available on the Laser Processing Market.

Acrylic & Plastics

Pungent Fumes need Activated Carbon Filtration

Metals & Composites

Fine Dust requires HEPA & Multi-Stage Filtration

Laser Cleaning & Welding

Even Low-Emission processes Benefit from Extraction

Ready for Cleaner, Safer Laser Operations?

Key Features of MimoWork Laser Fume Extractors:

Laser Engraver Fume Extractor

1. Compact Size & Quiet Operation:

Easy to move and operate without disturbing your environment.

2. Powerful Suction:

High-efficiency brushless fan delivers strong airflow.

3. Adjustable Air Volume:

Control air volume manually or remotely for your convenience.

4. User-Friendly LCD Display:

Shows air volume and machine power at a glance.

5. Safe & Stable:

Filter block alarm alerts you when it’s time to replace the filter.

6. Four-Layer Filtration:

Effectively purifies smoke, odors, and harmful gases.

7. Exceptional Filtration Efficiency:

99.7% filtration of smoke and dust at 0.3 microns.

8. Cost-Effective Maintenance:

Replaceable laser exhaust filter element for easy upkeep and lower costs.

Overview of MimoWork Laser Fume Extractors:

2.2KW Industrial Fume Extractor

Suitable for the Following Laser Machine:

Flatbed Laser Cutter & Engraver 130

Fiber Laser Welding Machine

Fiber Laser Cleaning Machine

| Machine Size (mm) | 800 * 600 * 1600 |

| Input Power (KW) | 2.2 |

| Filter Volume | 2 |

| Filter Size | 325 * 500 |

| Air Flow (m³/h) | 2685 – 3580 |

| Pressure (Pa) | 800 |

| Cabinet | Carbon Steel |

| Coating | Electrostatic Coating |

3.0KW Industrial Fume Extractor

Suitable for the Following Laser Machine:

Contour Laser Cutter 160L

| Machine Size (mm) | 800 * 600 * 1600 |

| Input Power (KW) | 3 |

| Filter Volume | 2 |

| Filter Size | 325 * 500 |

| Air Flow (m³/h) | 3528 – 4580 |

| Pressure (Pa) | 900 |

| Cabinet | Carbon Steel |

| Coating | Electrostatic Coating |

4.0KW Industrial Fume Extractor

Suitable for the Following Laser Machine:

Flatbed Laser Cutter 130L

Flatbed Laser Cutter 160L

| Machine Size (mm) | 850 * 850 * 1800 |

| Input Power (KW) | 4 |

| Filter Volume | 4 |

| Filter Size | 325 * 600 |

| Air Flow (m³/h) | 5682 – 6581 |

| Pressure (Pa) | 1100 |

| Cabinet | Carbon Steel |

| Coating | Electrostatic Coating |

5.5KW Industrial Fume Extractor

Suitable for the Following Laser Machine:

Flatbed Laser Cutter 130L

Flatbed Laser Cutter 160L

| Machine Size (mm) | 1000 * 1000 * 1950 |

| Input Power (KW) | 5.5 |

| Filter Volume | 4 |

| Filter Size | 325 * 600 |

| Air Flow (m³/h) | 7580 – 8541 |

| Pressure (Pa) | 1200 |

| Cabinet | Carbon Steel |

| Coating | Electrostatic Coating |

7.5KW Industrial Fume Extractor

Suitable for the Following Laser Machine:

Flatbed Laser Cutter 130L

Flatbed Laser Cutter 160L

| Machine Size (mm) | 1200 * 1000 * 2050 |

| Input Power (KW) | 7.5 |

| Filter Volume | 6 |

| Filter Size | 325 * 600 |

| Air Flow (m³/h) | 9820 – 11250 |

| Pressure (Pa) | 1300 |

| Cabinet | Carbon Steel |

| Coating | Electrostatic Coating |

Interested in Laser Fume Extractor?

E-mail: info@mimowork.com

WhatsApp: [+86 173 0175 0898]

MimoWork fume Extractors can connect Directly to the MimoWork Laser System.

They are also Compatible with Other Brands of Fiber and CO2 Laser Cutting Machines.

Share your Working Table Size, Material, Mechanical Ventilation Setup, and any other Specifications, and we’ll recommend the Best Option for you!